How To Identify A Muncie Transmission

Few things are as fun in a classic Muscle car than rowing through a Muncie 4-speed. With many of today’s cars being automatics, the joy of having that direct input to change the gears when and how you want to. The Muncie transmission is a bit outdated by today’s standards with no overdrive, but still holds a place in the restoration and sentimental value markets.

Many people know about Muncie transmissions and the famous M22 “rock crusher” transmission that has straighter cut gears that allows you to bang the gears without pushing in the clutch. We wanted to find out more about Muncie transmissions and found this article on Motortrend.com that shows everything you need to know about the beloved Muncie transmission.

Written by Jim Smart – Courtesy of Summit Racing

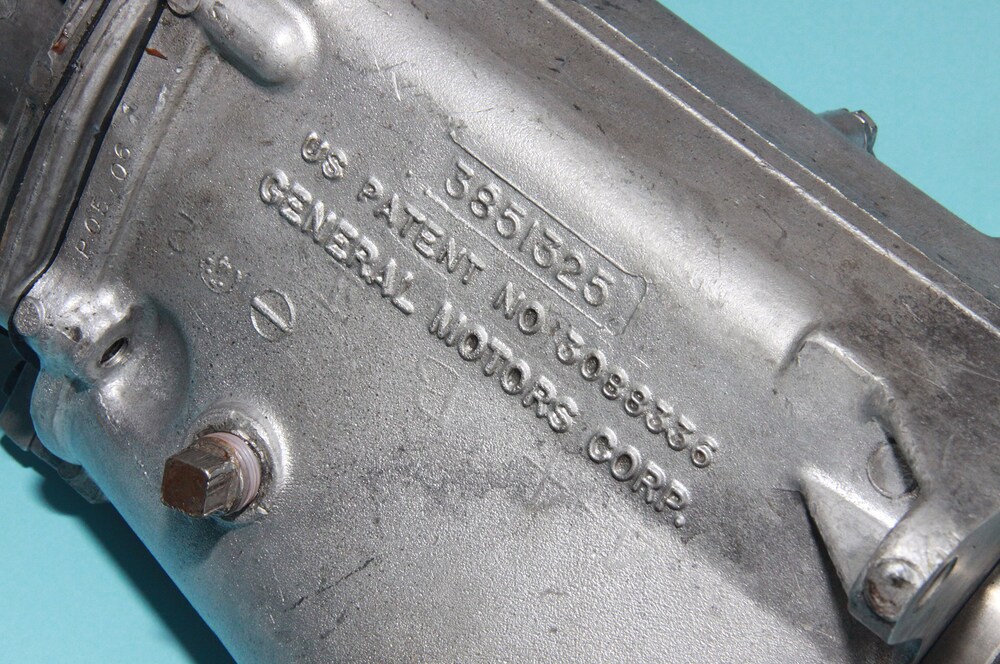

According to Paul Cangialosi, Muncie transmission historian, technician, and author of Muncie 4-Speed Transmissions: How to rebuild and modify, the Muncie four-speed transmission has its roots back to 1935 and the U.S. patent number 3,088,336 along with an engineer named James W. Fodrea. This patent number, according to Cangialosi, can be found cast into most Muncie four-speed main cases. Fodrea’s legacy is far-reaching, extending into popular transmissions around to this day, yet most have no idea who he was.

According to Cangialosi, two companies, Borg and Beck and Warner Gear, merged in 1928 to form BorgWarner. The T-85 three-speed transmission was one result of that merger. The T-10 four-speed was an evolution of the T-85 three-speed transmission, with both of these transmissions being quite similar in appearance. If you’ve ever looked at a BorgWarner T-10 and a Muncie four-speed and gotten them mixed up, you are not alone because the Muncie (M20, M21, and M22) is a direct descendant of the T-10 according to Cangialosi. The Saginaw four-speed box is quite similar to both the T-10 and Muncie four-speed transmissions. However, neither compares to the Muncie in terms of strength.

That the Muncie has much in common with the T-10 is no accident. It was a matter of economics when Chevrolet needed a four-speed manual transmission for the Corvette in the mid-1950s. According to Cangialosi, GM took the basic T-10 design and beefed it up to conceive the Muncie M20 and M21 four-speed transmissions, which arrived in 1963.

GM’s goal with the Muncie four-speed was to produce a better shift employing larger synchro cones. He tells us both the M20 wide-ratio and M21 close-ratio transmissions were first offered in 1963. The M22 Rock Crusher would come later to accommodate the heavy twist of Chevrolet’s big-blocks in the mid-1960s.

The M20 and M21 transmissions produced from 1963-’74 are easy to identify in both wide- and close-ratio units. The M22 to come later in 1967-’74 is also a close-ratio unit, but much stronger than the M21, with a higher torque capacity.

Because the Muncie has so much in common with the T-10 and even similar Saginaw boxes, it is easy to get this guy mixed up with non-Muncie units. Although the Muncie’s bloodline goes way back, this legendary gearbox entered service for the Chevrolet Division in 1963. In fact, 1963 is a standalone year because changes in this box came almost immediately for 1964, beginning with the front bearing retainer, which was aluminum for 1963 and became cast-iron in 1964. The bearing bore size was also one year only with a #6207-style input shaft bearing, according to Cangialosi.

The early production Muncie four-speed case is the small-bore unit and can be identified by the GM casting number 3831704 (see Muncie M20/M21/M22 Main Case Identification chart). The large-bore Muncie came into production in 1964-’65 and became the standard from then on through the end of production in 1974. What makes the small-bore and large-bore case Muncies different is the input shaft bearing size and first gear, which rode on the mainshaft void of a bushing for 1963. For 1964 and beyond, it rode on a bushing between it and the mainshaft.

Cangialosi explains there were two basic mainshafts produced for the M20, M21, and M22 transmissions (see Input Shaft Identification chart). From 1963-’70, the Muncie was fitted with a 27-spline mainshaft and must have the corresponding slip yoke. For 1971-’74, a larger diameter, 32-spline mainshaft was employed along with the corresponding yoke. Because this mainshaft is larger, you’re also going to need larger bushings and seals. Keep this in mind when you’re searching for a Muncie transmission.

Cangialosi tells us all M20 and M21 transmissions were produced with both 10- and 26-spline input shafts. The 26-spline input shaft came into production later in the 1970s for the M20 and M21.

What you will find in your search for the right Muncie four-speed is conflicting information from different sources. Before you here are the basics of Muncie M20, M21, and M22 four-speed transmissions. Glean the basics and use them in your research. Expect to find various combinations out there because these high-performance four-speed transmissions have been thrashed, trashed, and rebuilt through the decades. You’re going to find various combinations of main cases, tailshaft housings, and side covers coupled with variations inside of each case. Pure dumb luck will lead you to a completely unmolested Muncie.

One more way to identify the Muncie is via stamped codes in the case, which indicate when the transmission was built at Muncie (see How To Read Muncie Build Date Codes chart). According to Cangialosi, the date was based on model year, not necessarily the calendar year.

Of course, restorers and rebuilders will tend to re-stamp the date code to suit a particular restoration. This can add confusion to what you’ve found. Muncie transmissions also tend to get performance improvements such as a gear ratio change and stronger internal parts. This is when you have to remove the side cover to see what’s inside. Examine the input and output shafts to see if you’ve found the box you want.

And finally, if forced to choose between a Muncie or the BorgWarner T-10, it is suggested you choose the Muncie due to its brute strength. The Muncie was originally a stronger alternative to the T-10 and Super T-10 because it could take the torque. If you find an M22, you have the ultimate Muncie designed for the high torque of a big-block that will bolt to your small-block.

For more information or any help putting a Muncie in your classic car, give our friendly techs a call at (203) 235-1200!

1. The classic Muncie four-speed transmission in all its many forms generally looks like this (this one provided by Anaheim Gear), though applications will vary in appearance. Cases are either small-bearing (1963) or large-bearing (1964-’74). The cases offer a broad range of interchangeability. Muncie transmissions from 1971-’74 have the larger 32-spline output shaft.

2. The main case will sport a seven-digit casting number (found above the US Patent No), which is not a GM part number. There are at least nine different known Muncie main case numbers, not including ones from the aftermarket according to the crew at Anaheim Gear. Author and technician Paul Cangialosi tells us the original U.S. patent for the Muncie four-speed was filed on November 29, 1957, and approved May 7, 1963. Main cases manufactured prior to May 7, 1963, will say Patent Pending. Anything after that time period will say US Patent No 3088336.

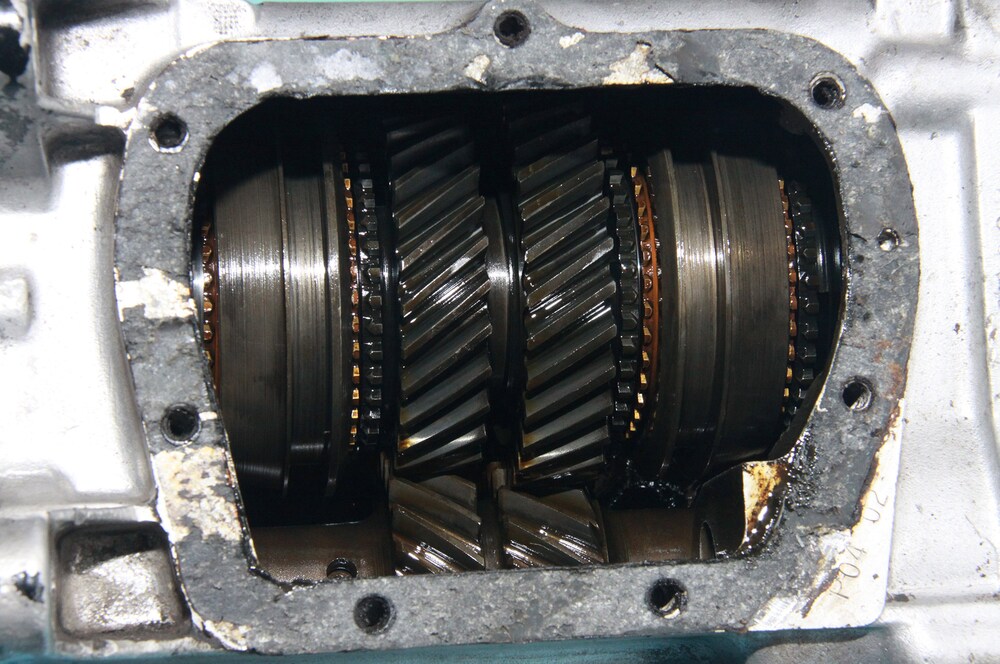

3. The Muncie four-speed, like the T-10, is a side-loading transmission. Remove the side cover and forks for a look at the geartrain. Removal of the front bearing cover is where disassembly begins. This frees up the geartrain.

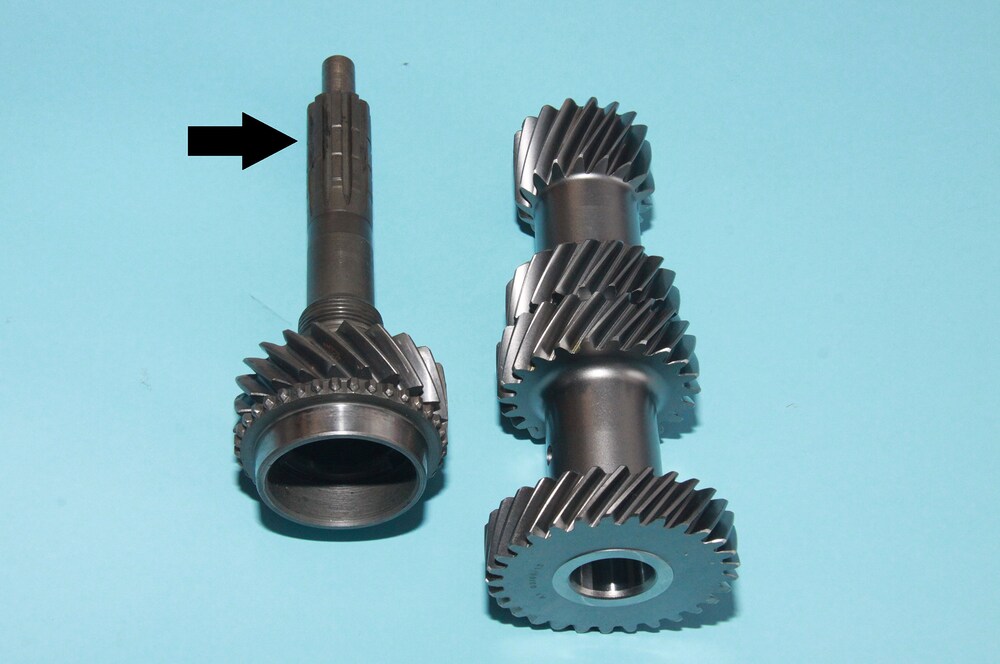

4. The guys at Anaheim Gear tell us there are seven total Muncie input shaft options. Shown here is the M20 10-spline wide-ratio input shaft and counter gear. There is also a fine-tooth 26-spline input shaft employed from 1971-’74.

5. If you examine the 1966-’70 wide-ratio M20 input shaft, there are two grooves cut amid the 10 splines. The 1963-’65 M20 input shaft will not have grooves. And keep in mind that not all will sport these grooves. From 1971 through the end of production in 1974, the M20 got the 26-spline input shaft.

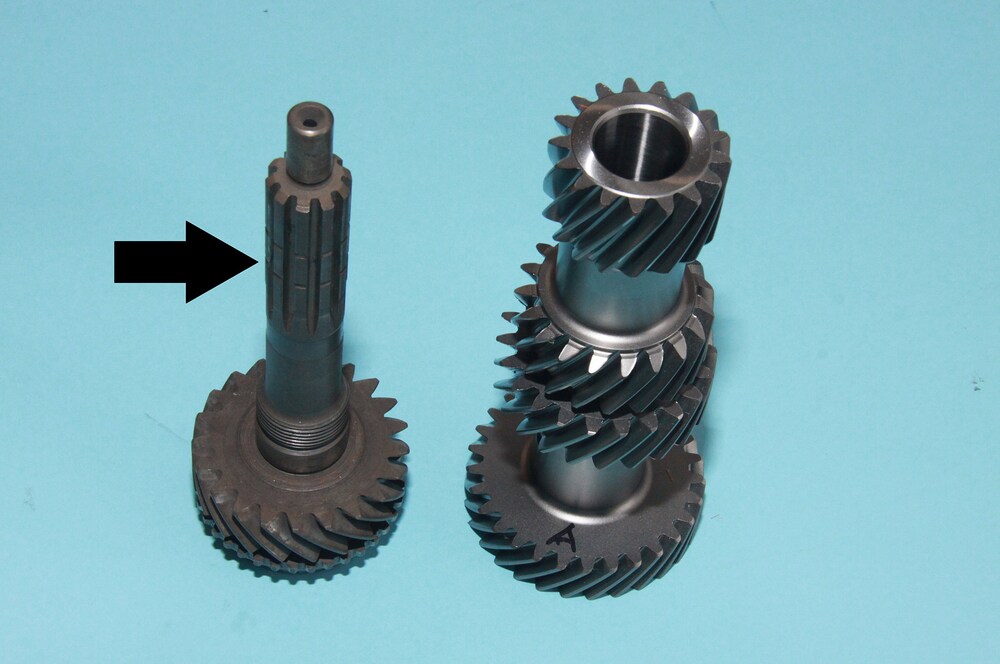

6. This is the M21 10-spline input shaft with a single groove and the applicable 27/22/19/17-tooth countershaft.

7. From left to right are the three basic Muncie input shaft/countershaft combinations. On the left is the M20 countershaft and 10-spline input shaft. In the middle is the M21 countershaft and input shaft. On the far right is the M22 26-spline input shaft. In the 1970s, virtually all Muncie four-speeds had 26-spline input shafts.

8. The M22 Rock Crusher 26-spline input shaft sports a wider gear for greater torque capacity. Just because you’ve found a 26-spline input shaft does not mean you’ve found an M22 input shaft, which is made of a stronger alloy. The standard 10-spline input shaft found its way into new Muncie M20 and M21 transmissions from 1971-’74.

9. Here’s another view of the M22’s input shaft and countershaft. The 26-spline input shaft yields greater torque capacity via the number of teeth and greater surface area.

10. Side-by-side are the two countershaft support sizes, which are 7/8-inch (left) and 1.000-inch (right).

11. Here’s a typical Muncie gearset consisting of First, Second, and Third gear.

12. On the left is the M20 countershaft, which is easily identified by the larger 29-tooth gear. On the right is the M22 countershaft with 27-teeth. When you have the two side-by-side it becomes obvious which is which.

13. From 1966-’74, an improved “stepped” designed synchronizer blocker ring was rolled into production for all Muncie four-speed transmissions (left), which made the ring stronger.

14. This is an M21 with 10-spline input shaft and cast-iron bearing retainer. Note the single groove, meaning an M21 close-ratio.

15. Tailshaft housings will vary based on original application. There were a total of six types. You can use a variety of stock and aftermarket shifters on any of the Muncie tailshaft housings. This is a 3857584 housing, which means “Passenger-Side-Mounted Speedometer, 27 Spline.”

16. There are six known Muncie side covers. Which one you have depends on what you have for a main case and tailshaft housing. Two are early style side covers. Four are late model.

17. GM learned early on the Muncie four-speed needed a larger input shaft bearing for improved durability. On the right is the small input shaft bearing, which is 1963 only.

18. If you have a 1963 Muncie that needs an input shaft bearing retainer, all is not lost if you can’t find the 1963 aluminum bearing retainer. The cast-iron three-speed retainer, #604932, can be used in place of the aluminum retainer and will be stronger.

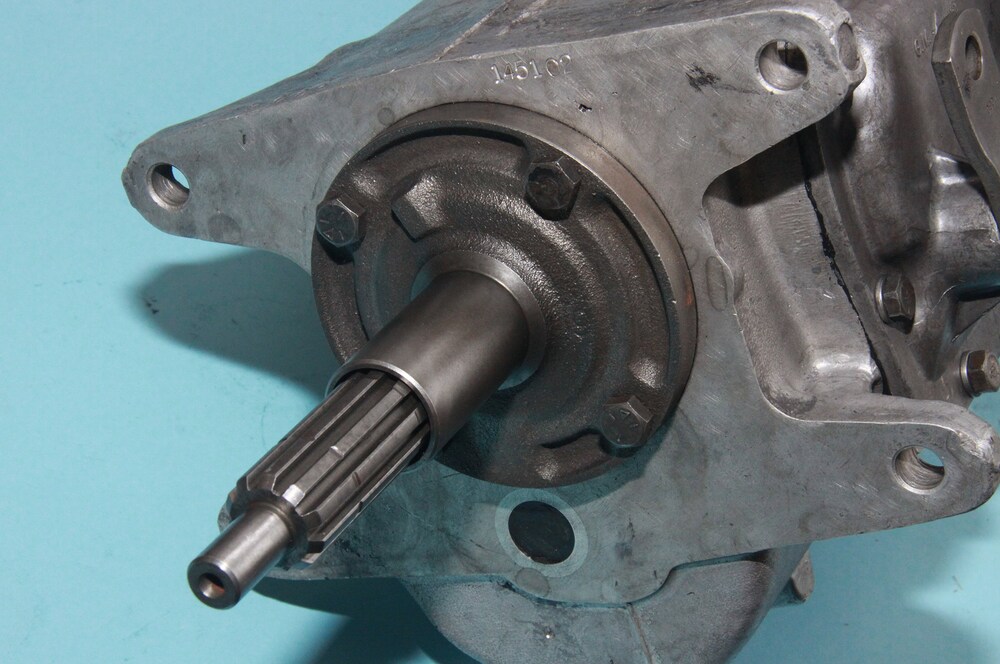

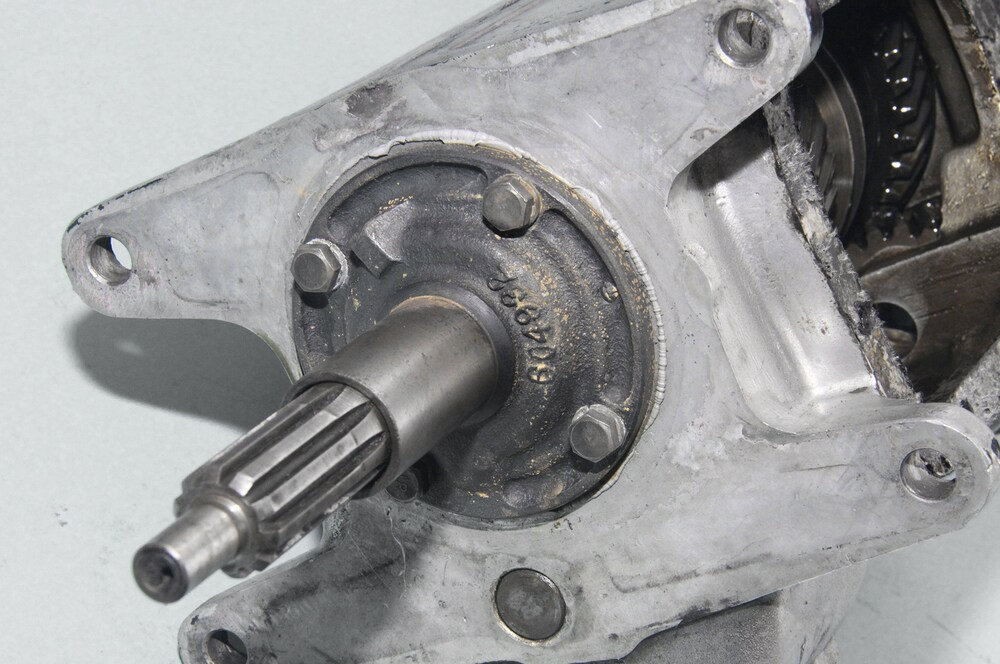

19. You don’t have to search the classifieds or a junk pile to find a suitable bellhousing for your Muncie M20, M21, or M22. We inventory all kinds of cast-aluminum and steel bellhousings for the Muncie. This is a cast-aluminum bellhousing, which offers an OEM look for Chevrolet applications.

20. We also offer a wide variety of slip and differential yokes for Muncie four-speeds.

21. Looking for a Muncie shifter? We have those too along with a full line of Muncie parts.

Muncie Four-Speed Gear Ratios

| M20 Wide-Ratio 1963-’65 | |

| First Gear | 2.56:1 |

| Second Gear | 1.91:1 |

| Third Gear | 1.48:1 |

| Fourth Gear | 1:01 |

| Reverse Gear | 3.16:1 |

| M20 Wide-Ratio 1966-’74 | |

| First Gear | 2.52:1 |

| Second Gear | 1.88:1 |

| Third Gear | 1.46:1 |

| Fourth Gear | 1:01 |

| Reverse Gear | 3.11:1 |

| M21 Close-Ratio | |

| First Gear | 2.20:1 |

| Second Gear | 1.64:1 |

| Third Gear | 1.28:1 |

| Fourth Gear | 1:01 |

| Reverse Gear | 2.27:1 |

| M22 Rock Crusher | |

| First Gear | 2.20:1 |

| Second Gear | 1.64:1 |

| Third Gear | 1.28:1 |

| Fourth Gear | 1:01 |

| Reverse Gear | 2.27:1 |

Muncie M20/M21/M22 Main Case Identification

| GM Casting Number | Year(s) Produced | Description |

| 3831704 | 1963 | Patent Pending, 7/8-inch Countershaft Bore Aluminum Front Bearing Retainer Small Input Bearing |

| 3839606 | 1963-’64 | Patent Pending, 7/8-inch Countershaft Bore Cast-Iron Bearing Retainer toward the end of 1963 Large Input Bearing |

| 3851325 | 1964-’65 | Patent Pending, 7/8-inch Countershaft Bore used mostly in 1964 Large Input Bearing |

| 3851325 | 1964-’65 | Patent Number, 7/8-inch Countershaft Bore Large Input Bearing |

| 3864848 | 1965 | Patent Number, 7/8-inch Countershaft Bore Large Input Bearing |

| 3864___ | 1965 | Patent Number, 7/8-inch Countershaft Bore Last 3 Digits Milled Off Of Case Large Input Bearing |

| 3885010 | 1965-’67 | Patent Number, 1.000-inch Countershaft Bore Large Input Bearing |

| 3925660 | 1968-’70 | Patent Number, 1.000-inch Countershaft Bore Large Input Bearing |

| 3925661 | 1970-’74 | Patent Number, 1.000-inch Countershaft Bore Large Input Bearing Larger 32-Spline Output Shaft |

Tailshaft Housing Identification

| GM Casting Number | Year(s) Produced | Description |

| 3831731 | 1963 | Thin Fin Tailshaft, Driver-Side-Mounted Speedometer, 27 Spline Output |

| 3846429 | 1963 | Thin Fin Tailshaft, Driver-Side-Mounted Speedometer, 27 Spline Output |

| 3846429 | 1963-’65 | Thick Web Tailshaft, Driver-Side-Mounted Speedometer, 27 Spline Output |

| 9779246 | 1964-’65 | Pontiac Catalina Long Tailshaft, Side-Mounted-Speedometer, 27 Spline Output |

| 3857584 | 1966-’70 | Passenger-Side-Mounted Speedometer, 27 Spline Output |

| 3978764 | 1970-’74 | Passenger-Side-Mounted Speedometer, 32 Spline Output |

Side Cover Identification

| GM Casting Number | Description |

| 3831707 | Early Side Cover 1963-’65 |

| 3884685 | Early Side Cover Used With 3857584 Tailshaft Housing |

| 3950306 | Late Side Cover – No Switches |

| 3952642 | Late Side Cover – Long Boss – With A Transmission Controlled Spark Switch |

| 3952648 | Late Side Cover – Short Boss – With A Transmission Controlled Spark Switch |

| 335308 | Late Side Cover – Long Boss With A Neutral Safety Switch |

Input Shaft Identification

| Years | Type | Grooves | Input Shaft Splines | Output Tooth Count | Output Shaft Splines |

| 1963-’65 | M20 | None | 10 | 24 | 27 |

| 1966-’70 | M20 | Two | 10 | 21 | 27 |

| 1970-’74 | M20 | Two | 26 | 21 | 32 |

| 1963-’70 | M21 | One | 10 | 26 | 27 |

| 1970-’74 | M21 | One | 26 | 26 | 32 |

| 1967-’70 | M22 | None | 10 | 26 | 27 |

| 1969-’74 | M22 | None | 26 | 26 | 32 |

Countershaft Identification

| Type | Number of Gear Teeth (1st/2nd/3rd/4th) |

| Early M20 | 29/22/19/17 |

| M20 | 25/22/19/17 |

| M21 | 27/22/19/17 |

| M22 Rock Crusher | 27/22/19/17 |

Muncie Build Date Codes

| From 1963-’66 | |

| Characters | Description (i.e., Date Code P0525) |

| 1 | Build facility (i.e., P = Muncie Transmission Plant) |

| 2-3 | Month code it was assembled (i.e., 05 = May) |

| 4-5 | Day code it was assembled (i.e., 25 = 25th Day) |

| From 1967-’68 | |

| Characters | Description (i.e., Date Code P8D12) |

| 1 | Build facility (i.e., P = Muncie Transmission Plant) |

| 2 | Model year code (i.e., 8 = 1968) |

| 3 | Month code it was assembled (i.e., D = April) (Beginning in 1967, Muncie used letter codes for the month code: A=Jan, B=Feb, C=Mar, D=Apr, E=May, H=June, K=July, M=Aug, P=Sep, R=Oct, S=Nov, T=Dec) |

| 4-5 | Day code it was assembled (i.e., 12 = 12th Day) |

| From 1969-74 | |

| Characters | Description (i.e., Date Code P2M03A) |

| 1 | Build facility (i.e., P = Muncie Transmission Plant) |

| 2 | Model year code (i.e., 2 = 1972) |

| 3 | Month code it was assembled (i.e., M = August) |

| 4-5 | Day code it was assembled (i.e., 03 = 3rd Day) |

| 6 | Gear ratio set (i.e., A=M20) (This code was added to identify ratios. Some early 1969 transmissions did not have this code. A=M20 B=M21, C=M22) |