In-Tank Retrofit Fuel Pump Install

Holley In-Tank Retrofit Fuel Pump Install The hot ticket nowadays is fuel injection. Whether that’s a full on LS swap, or adding a throttle body

Choosing the right tools for the job is important when it comes to installing gaskets or seals and not having them leak. Whether you’re a seasoned technician or new to the field, having the necessary tools on hand is essential for any sealing job that comes your way.

Scrapers are invaluable for removing old gasket material, carbon buildup, and dirt from sealing surfaces. Flat blade paint removal-type scrapers and carbide scrapers are commonly used, along with razor blades mounted in holders for paper gaskets. It’s important to maintain a flat, low angle when using these tools to avoid creating gouges on the surface. Plastic scrapers or plastic razor blades should be used on aluminum surfaces to prevent damage.

Before you start removing the gaskets with a scraper or wire wheels, you’ll want to cover up the open passages such as an intake runner. You don’t want gasket material going inside the engine and causing more issues.

Wire wheels and brushes are ideal for heavy cleaning tasks, such as removing carbon, dirt, and old gasket material. Coarse wire wheels are suitable for cast iron surfaces, while fine wire wheels can be used on both cast iron and aluminum surfaces. Brass hand wire brushes are effective for cleaning RTV from aluminum and plastic parts without causing damage.

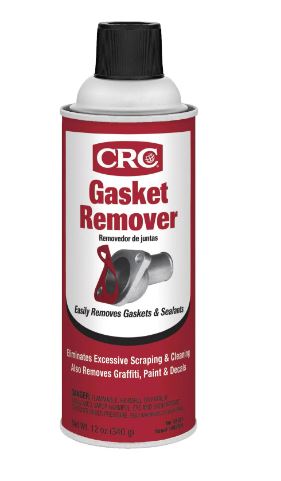

Once the gasket has been removed, now is the time for a cleaning solvent such as brake cleaner. Remember to always use these in an extremely well ventilated area.

Cleaning solvents are great for ensuring a clean and dry sealing surface before gasket installation. It’s important to choose a solvent that doesn’t leave behind any residue or oily finish. Additionally, using lint-free rags for wiping down surfaces helps prevent contamination.

Lastly, before installing your new gasket, read the directions and see how the manufacturer recommends installation. Some gaskets need RTV in conjunction with the actual gasket. Some types of gaskets work better for certain scenarios than others. Or some gaskets you don’t want to use RTV at all.

Other handy tools include small pocket screwdrivers and dental-type picks for removing O-rings and RTV from crevices, as well as a shop vacuum for cleaning engine parts after the job is done. Running a magnet over the castings can help pick up any small metal particles that the vacuum may have missed.

It’s crucial to avoid using abrasive tools such as Scotch-Brite pads, Roloc discs, body grinders, sandpaper, screwdrivers, or Roloc bristle discs for cleaning sealing surfaces. These tools can quickly remove metal and create uneven surfaces that prevent gaskets from sealing properly, potentially causing damage to the engine in the long run.

If you need any help with gaskets or getting something leak to seal, give our friendly techs a call at (203) 235-1200 and hop on SS396.com for all your part needs!

Holley In-Tank Retrofit Fuel Pump Install The hot ticket nowadays is fuel injection. Whether that’s a full on LS swap, or adding a throttle body

On July 6, 2019, Daniel was at the Donut Derelicts car gathering in Huntington Beach, CA. He had sold his ’49 Shoebox Ford about a

Don’t Freeze Up – Sale going on this Weekend Only! Get $15 Off* when you apply the Code: WWS15 during checkout on orders over $199. Max Discount $15. Valid until 12/22/24 (9pm ET). Don’t miss out on this opportunity to save on the essential parts that keep your restoration moving forward.