Protected: Restoration Shop Program Application

There is no excerpt because this is a protected post.

In the intricate dance of an internal combustion engine, the camshaft plays a crucial role, orchestrating the precise movement of valves, intake, and exhaust to create the symphony of power. Understanding the anatomy and functionality of camshafts delves into the core of engine design and performance.

1. Core Structure:

The camshaft, typically made of high-strength alloy steel, rotates within the engine block. It is strategically positioned, usually above the crankshaft, with lobes protruding along its length.

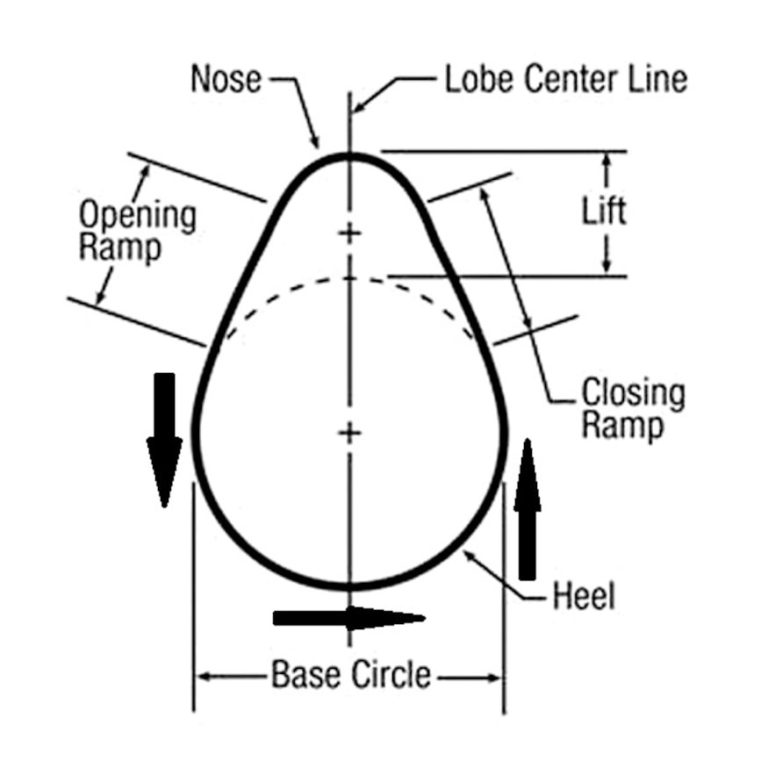

2. Lobes:

The key elements are the lobes, which determine the timing and duration of valve opening and closing. Camshaft lobes are meticulously designed with specific profiles, each tailored to the engine’s requirements.

3. Journals and Bearings:

The camshaft rests on journals, supported by bearings that reduce friction during rotation. Proper lubrication is vital for longevity and smooth operation.

4. Timing Gear:

Connected to the crankshaft by a timing chain or belt, the timing gear synchronizes the rotational movement of the camshaft with the engine’s cycle.

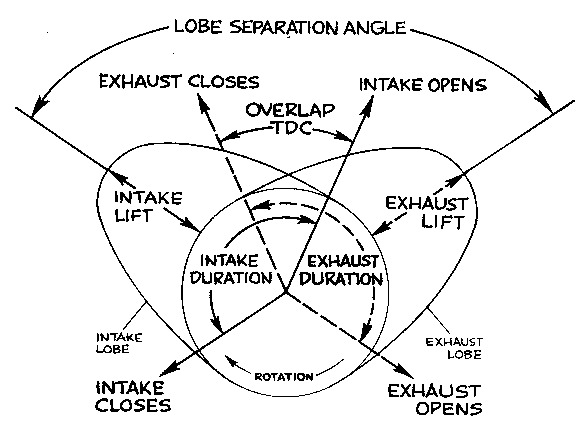

Duration:

Overlap:

1. Flat-Tappet Cams:

Traditional and cost-effective, flat-tappet cams have a flat bottom on the cam lobes. They require careful break-in due to higher friction during initial use.

2. Roller Cams:

Roller cams use cylindrical, roller-style lifters, reducing friction and allowing for more aggressive lobe profiles. They excel in high-performance applications.

3. Hydraulic vs. Solid Lifters:

Camshafts can employ hydraulic or solid lifters. Hydraulic lifters use engine oil pressure for automatic valve lash adjustment, while solid lifters require manual adjustment but are preferred in racing for precise control.

1. Valve Timing:

Accurate valve timing is fundamental. The camshaft dictates when intake and exhaust valves open and close, ensuring optimal fuel combustion and exhaust expulsion.

2. Engine Phasing:

The relationship between the crankshaft and camshaft, known as engine phasing, is critical. Proper phasing ensures synchronization and prevents mechanical issues.

3. Variable Valve Timing (VVT):

VVT systems dynamically adjust camshaft timing, optimizing performance at different engine speeds. This technology enhances efficiency, power, and fuel economy.

If you need help with your classic, be sure to hop on SS396.com or give our friendly techs a call at (203) 235-1200!

There is no excerpt because this is a protected post.

A-Arms, Roll Center, Camber Gain, and How to Improve Them Suspension geometry is one of the most misunderstood and most important parts of how a

From Generator to Alternator on ’60s & ’70s GM Vehicles Before using alternators, in the 1950s and early 1960s, GM vehicles used DC generators (often