Measure Twice, Cut Once

If you’ve swapped your engine, transmission, or rearend, there’s a good chance that you need to have a different length driveshaft. If it’s too short or too long, you will have problems. A driveshaft is like Goldie Locks and the Three Bears. This driveshaft is too long, this one is too short, and this one is just right! Ordering a custom-length driveshaft is a pretty simple process through Inland Empire Driveline.

Measure It Up

Before you get to measuring, you need to have the car loaded down and sitting at ride height. This means the engine and transmission should be installed, all suspension installed, and most of the interior. If the suspension isn’t where it’s going to live, then you risk having a driveshaft that’s too short or too long.

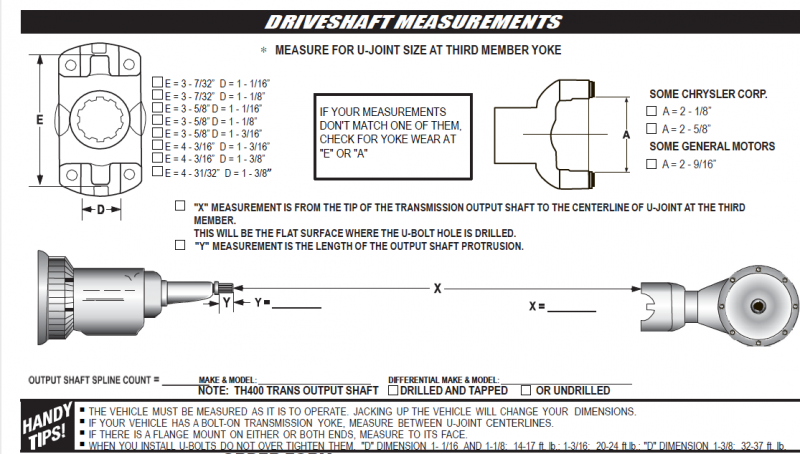

For the big measurement, you’ll want to measure from the tip of the output shaft on the transmission to the face of the yoke where the U-Bolts go through it. In addition, you need to measure how much the output shaft is sticking out of the transmission along with how many splines are on the transmission.

On the rear end side, you’ll want to measure the overall width of the yoke, the inside-to-inside measurement, and the diameter where the U-Joints mount.

Non Measurement Data

Besides the measurements, there’s some other information that the manufacturer will need to know. Specifically what kind of power you’re putting out. The diameter of the driveshaft will vary with different power levels, and the material the driveshaft is made out of. Obviously a fairly stock weekend cruiser will have a much smaller diameter than a 1,000HP drag race car.

Having the correct length and power handling abilities in a driveshaft is a crucial part of your entire driveline. Without it, you aren’t going anywhere. And if it fails, it can cause catastrophic damage to your ride. If you have any other other questions give our friendly techs a call at (203) 235-1200 or hop on SS396.com for all your driveshaft needs.