Holley In-Tank Retrofit Fuel Pump Install

The hot ticket nowadays is fuel injection. Whether that’s a full on LS swap, or adding a throttle body injection unit to your traditional SBC/BBC combo. Fuel injection has a list of reasons why it’s better than a carburetor, but there’s also some draw backs.

One of those draw backs is they are a little more complicated. For example, they all require a high-pressure fuel pump to feed. A mechanical engine-driven pump simply can’t supply the pressure needed for these fuel injection systems. There are options to purchase an entirely new tank that has provisions for an in-tank pump. But what if you’re on a budget and want to use what you already have? Holley’s Retrofit In-Tank Fuel Pump is a great solution for that.

In-Tank Vs In-Line Fuel Pumps

Why an in tank pump? Surely adding an in-line pump is an easier solution right? Yes it’s easier, but can have a host of issues and we don’t like them. Before you get in a huff, there’s plenty of people who run them, swear by them, and have never had an issue. After we had an issue though, we swore them off.

Simply put, in-line pumps are designed to push fuel, not pull. The pump needs to be gravity fed; if the pump is on the fuel rail somewhere then it’s having to pull that fuel which can overwork it or shorten it’s lifespan.

Another major concern is vapor lock. Yes, vapor lock on a fuel-injected engine. What happens is the fuel sitting in the tank is getting warmed up by driving, especially if it has a return line. Then when the fuel is under vacuum, it lowers the boiling point to where you can experience vapor lock. We’ve had it happen and it’s a frustrating problem. To remedy that, it’s better to have the pump submerged in the fuel in the tank where it can’t draw a vacuum and the fuel helps it stay cool.

Retrofit In-Tank Pump

Luckily, Holley has come up with an easy solution to this that allows you to install a high pressure fuel pump into just about any fuel tank you can imagine. The absolute first step is to disconnect the battery, drain the fuel tank, and drop it out from under the car. One thing to note is that the Holley pump does require at least a 7″ deep tank to fit the pump properly inside.

The next step is to drill a hole. For this pump it required a 3.25″ hole, which we made with a hole saw. Take some time to deburr this and keep it clean. Most classic Chevy tanks have ribs that you’ll need to consider. As long as they are less than 1/4″deep, then the foam gasket will conform and still seal up nicely. How that works is when you install the assembly and start to tighten the bolts, small arms swing out and pinch the underside of the tank clamping down for a leak-free seal.

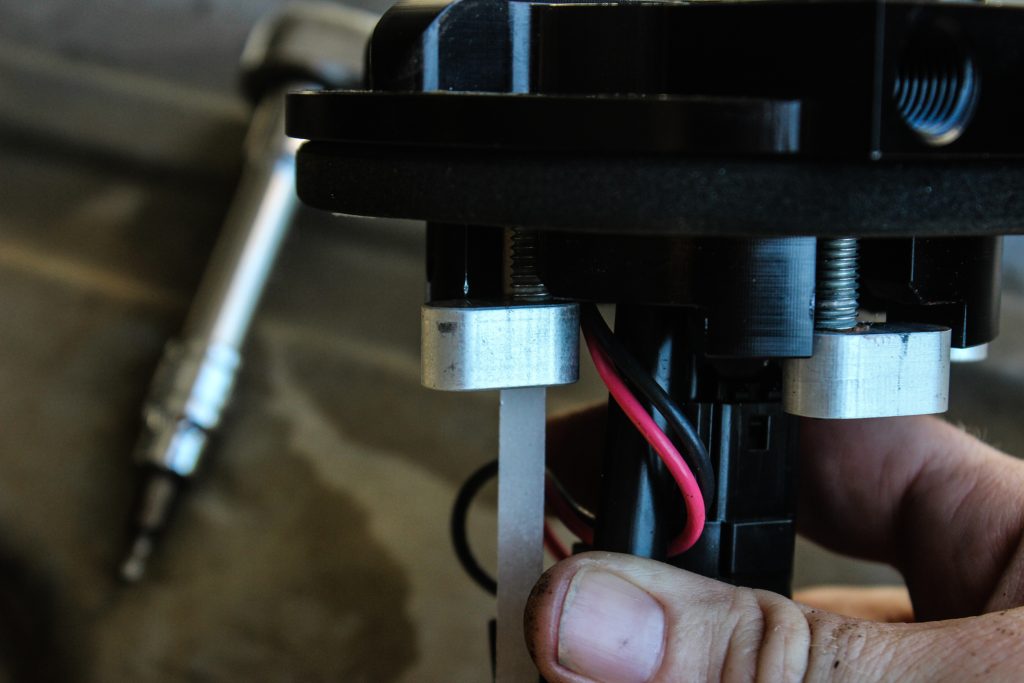

The assembly includes three ports on the top of it, all 1/4″ NPT. One is your supply, one is return, and the last is the vent. Then there is a power and ground wires. Before dropping the assembly in, you’ll have to do some measuring and trimming to get the pump to the right height. Holley made this easy with a table. On the bottom of the pump is a big piece of Hydra-Mat which serves as a filter but also will grab and suck up any fuel it touches. You can actually have just a corner of it in fuel and the pump can pull from there.

Once all the measuring and cutting has been, it’s just a matter of dropping the assembly into the tank and tightening down the bolts. Another consideration here is now this assembly will sit a little bit above the tank which could hit the trunk floor. Holley thought of this as well and included a few strips of extra thick foam that will help space the tank down a little bit to provide that extra space.

When you need an EFI Fuel Pump or if you want to upgrade to a EFI Fuel Tank, make sure to hop on SS396.com for all your fuel needs or give our friendly techs a call at (203) 235-1200!